CNC Router Machine: Precision Crafting Guide

CNC Router Machine: Precision Crafting Guide

Blog Article

Introduction

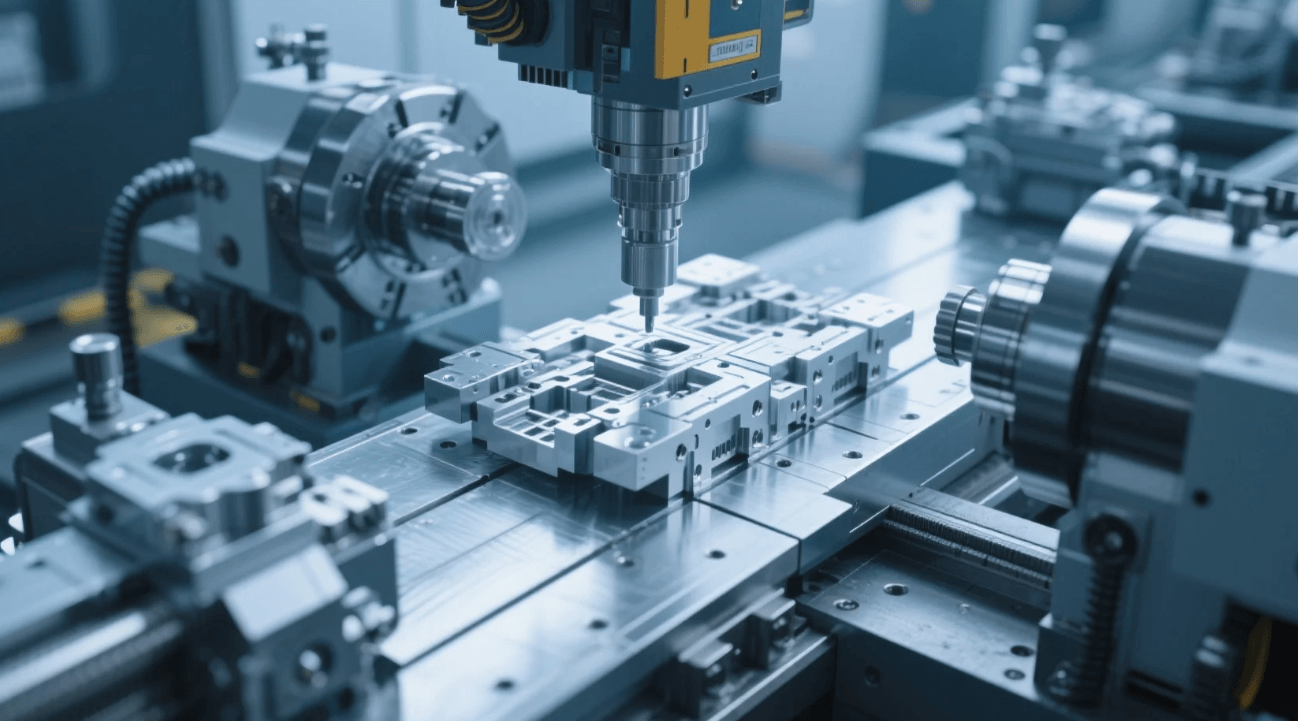

In modern precision manufacturing, a CNC router machine has become an indispensable tool for producing intricate parts with micron-level accuracy. From aerospace components to customized furniture in smart factories, these machines automate complex cutting, drilling, and engraving tasks. By leveraging computer control and advanced tooling, CNC routers enhance efficiency, reduce waste, and support flexible production runs. This article explores the essential features of CNC router machines, their core components, applications in precision industries, buying considerations, and best practices—providing valuable insights for manufacturing professionals.

Understanding CNC Router Machines

Definition and Operating Principle

A CNC router machine is a computer-controlled cutting device equipped with a spinning tool that moves along multiple axes to shape materials such as wood, plastics, composites, and metals. Its key advantage lies in translating CAD designs into precise G-code commands that drive the router’s movements, ensuring consistency and repeatability across production batches.

Core Components

-

Control System: A CNC controller (Siemens, Fanuc, or open-source platforms) interprets G-code and directs axis motors.

-

Axes and Motion Mechanics: Most machines feature three linear axes—X (left–right), Y (front–back), and Z (up–down)—while advanced models add rotary or A/B axes for 4- and 5-axis capabilities.

-

Spindle Unit: High-speed spindles (10,000–30,000 RPM) accommodate various cutting tools, from end mills to ball-nose cutters.

-

Tool Changer: Automated tool magazines swap bits during operations, reducing downtime and enabling complex toolpaths.

-

Motion Components: Linear rails, ball screws, and servo or stepper motors ensure precise, backlash-free movement.

-

Vacuum or Clamping Table: Secures workpieces; vacuum tables are popular for flat materials, while T-slot beds suit varied fixturing.

-

Dust Collection: Integrated extractors maintain visibility and machine longevity by removing chips and debris.

Key Features and Technical Advantages

Precision and Tolerance

-

Micron-Level Accuracy: Achieved through high-rigidity machines, precision ground components, and closed-loop feedback systems, enabling tolerances within ±0.01 mm.

-

Repeatability: Automated calibration routines and tool-length probing ensure every part matches the CAD model.

Automation and Productivity

-

Unattended Operation: Tool changers and part probing allow lights-out machining, maximizing uptime.

-

Multi-Tasking: 4- and 5-axis CNC router machines can perform undercuts and complex geometries in a single setup, minimizing repositioning.

Versatility and Material Range

-

Wide Material Compatibility: From ultra-hard composites and aluminum to wood and plastics.

-

Custom Toolpath Strategies: CAM software supports adaptive roughing, high-feed milling, and fine finishing passes, tailored to material properties.

Cost-Effectiveness

-

Reduced Scrap Rates: Accurate nesting and optimized toolpaths minimize waste material.

-

Lower Labor Costs: Automation reduces manual intervention and cycle times.

Core Applications in Precision Manufacturing

Aerospace Component Fabrication

-

Composite Layup Molds: CNC routers mill large molds from foam or aluminum with high surface quality.

-

Structural Brackets: Lightweight titanium or aluminum alloy parts are rapidly machined to tight tolerances.

Automotive Prototyping

-

Dashboard and Interior Panels: High-quality plastic and wood prototypes for design validation.

-

Custom Tooling and Fixtures: Jigs and fixtures improve assembly accuracy in production lines.

Industrial Tool and Die Making

-

Prototype Dies: Quick-turn tooling for short-run injection molding or stamping processes.

-

EDM Electrode Machining: Machining graphite or copper electrodes for electro-discharge machining.

Consumer Electronics

-

Enclosures and Housings: Precise machining of plastic, aluminum, or composite enclosures.

-

Heat Sink Milling: High-precision aluminum heat sinks with fine fin geometries for thermal management.

Signage and Woodworking

-

Custom Signage: Intricate routing on wood, acrylic, and foam for retail and architectural applications.

-

Furniture Components: Complex joinery, inlays, and ornamental patterns accurately reproduced.

Selecting the Right CNC Router Machine

Axis Configuration

-

3-Axis Routers: Ideal for simple pocketing, profiling, and drilling tasks.

-

4-Axis Routers: Add rotary A-axis for cylindrical work like columns and lamp posts.

-

5-Axis Routers: Enable machining of complex, compound-angle parts—critical in aerospace and medical device manufacturing.

Spindle Power and Speed

-

Power Rating: 2–15 kW spindles suit different materials; higher power for metals, lower for plastics and wood.

-

Speed Range: 8,000–24,000 RPM accommodates coarse to fine cutting tasks.

Work Envelope and Table Type

-

Bed Size: Choose based on maximum workpiece dimensions; common sizes range from 600×900 mm to 4,000×2,000 mm.

-

Table System: Vacuum tables for flat sheets; T-slot beds for flexible fixturing with clamps or fixtures.

Drive System and Accuracy

-

Servo vs. Stepper Motors: Servos offer better torque at high speeds and closed-loop feedback, yielding higher accuracy.

-

Ball Screws and Linear Guides: Ensure stiffness and precision; rolled screws are cost-effective, while ground screws provide superior accuracy.

Software Ecosystem

-

CAM Compatibility: Support for Mastercam, Fusion 360, or SolidCAM ensures efficient toolpath generation.

-

Machine Control Software: User-friendly HMI with DXF/G-code import, probe cycles, and diagnostics.

Best Practices for Operation and Maintenance

Proper Setup and Calibration

-

Machine Leveling: Ensure the machine base is perfectly level to avoid geometric errors.

-

Tool Probing: Use automatic tool length and diameter probes to calibrate offsets.

-

Workpiece Zeroing: Employ edge finders or laser probes for precise part origin definition.

Toolpath Optimization

-

Adaptive Clearing: Maintains constant tool engagement, reducing cycle time and prolonging tool life.

-

High-Speed Machining Strategies: Utilize trochoidal milling to minimize heat buildup in hard materials.

-

Finishing Passes: Apply dedicated finishing toolpaths at low stepovers (0.1–0.2 mm) for superior surface finish.

Routine Maintenance

-

Lubrication: Regular greasing of linear rails and ball screws prevents wear.

-

Spindle Care: Monitor vibration levels and replace bearings before failure.

-

Dust Control: Empty chip conveyors and clean filters daily to maintain airflow and prevent recirculation of abrasive particles.

Safety Measures

-

Enclosures and Guards: Prevent operator exposure to flying chips and coolant.

-

Interlock Switches: Stop the spindle if doors are opened.

-

Operator Training: Ensure personnel understand emergency stops, tool change procedures, and safe work practices.

ROI and Economic Considerations

Cost Analysis

-

Initial Investment: 3-axis machines start around $20,000; 5-axis systems can exceed $150,000.

-

Operating Costs: Include tooling, maintenance, and energy consumption.

-

Payback Period: Often 6–18 months, depending on utilization rates and labor savings.

Productivity Gains

-

Reduced Setup Time: Automated tool changes and probing cut setup by 50–70%.

-

Increased Throughput: Lights-out operations run overnight, maximizing utilization.

Quality Improvements

-

Consistent Part Quality: Automated routines eliminate human variability.

-

Reduced Rework: Precise machining decreases scrap rates, saving material costs.

Future Trends and Innovations

Integration with Additive Manufacturing

-

Hybrid Machines: CNC routers equipped with laser or powder deposition heads enable near-net shape builds followed by finishing passes.

-

Rapid Prototyping: Combining subtractive and additive processes reduces lead times.

IoT and Industry 4.0

-

Real-Time Monitoring: Sensors track spindle load, temperature, and vibration for predictive maintenance.

-

Data Analytics: Machine performance data optimizes cutting parameters and identifies bottlenecks.

Advanced Materials and Tooling

-

Graphene-Coated Tools: Offer higher wear resistance for abrasive composites.

-

High-Pressure Coolant: Improves chip evacuation and surface finish on difficult materials.

Conclusion

A CNC router machine represents a versatile, efficient solution for precision manufacturing across industries—from aerospace and medical devices to custom woodworking and signage. By understanding key features—axis configurations, spindle capabilities, and automation options—manufacturers can select the optimal machine for their needs. Adhering to best practices in setup, toolpath optimization, and maintenance ensures consistent part quality and maximizes ROI. As Industry 4.0 and hybrid machining advance, CNC routers will continue to evolve, offering even greater flexibility and productivity for modern precision applications.

FAQ

Q1: What materials can a CNC router machine handle?

A1: CNC routers process a wide range—including wood, plastics, composites, aluminum, and mild steels—depending on spindle power and tooling selection.

Q2: How is a 4-axis CNC router different from a 3-axis?

A2: A 4-axis machine adds a rotary axis (A-axis) for cylindrical or complex curved parts, reducing setups and enabling simultaneous contouring.

Q3: What maintenance is required for a CNC router machine?

A3: Routine tasks include lubrication of rails and screws, filter and dust collector cleaning, spindle vibration checks, and periodic calibration of probes.

Q4: Are CNC routers suitable for small shops?

A4: Yes. Desktop or compact models with reduced work envelopes provide precision capability in limited spaces at lower cost.

Q5: How do I improve surface finish on a CNC router?

A5: Use high-speed finishing passes with small stepovers, optimize toolpaths with high-speed strategies, and employ proper coolant or air blast for chip removal.